Innovations In The Marketplace

Global Bottling continues to expand its technology while striving to be an industry leader in multfunctional holders and insert assemblies. We took our research and development to the extreme by creating the Rycongb and Verixgb polymer multifunctional inserts and holder assemblies. As a result, we’ve become an organization where being innovative is paramount to our success. Through innovation we have helped and will continue to help our customers maintain and grow their businesses. Global Bottling’s best is the benchmark we must surpass tomorrow. As a global company we are committed to “holding the future of bottling”.

SUPERIOR RYCONgb

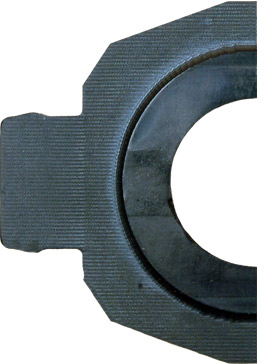

Global Bottling recognized the growing demand for the RYCONgb inserts and multifunctional holding system with little or no maintenance. In designing this holding system, we have a (patented) multifunctional wedge shape design with stainless steel 17-4 material and integrated holding clips. Quick removal and replacement of inserts is extremely easy and safe with our new loading device. RYCONgb inserts do not thermally check the glass and is non-oxidizing.

Global Bottling recognized the growing demand for the RYCONgb inserts and multifunctional holding system with little or no maintenance. In designing this holding system, we have a (patented) multifunctional wedge shape design with stainless steel 17-4 material and integrated holding clips. Quick removal and replacement of inserts is extremely easy and safe with our new loading device. RYCONgb inserts do not thermally check the glass and is non-oxidizing.

“OPERATIONAL EXCELLENCE, EXCEEDING CUSTOMER EXPECTATIONS, MEASURABLE PERFORMANCE, AND CONTINUAL IMPROVEMENT OF QUALITY BUSINESS SYSTEMS.”

PREMIUM VERIXgb

Global Bottling VERIXgb for the glass handling industry is a new revolutionary high temperature polymer composite capable of sustaining temperatures up to 1000F (530 C.)

The specially formulated composite has the capability of increasing plant reliability while reducing overall cost of manufacturing.

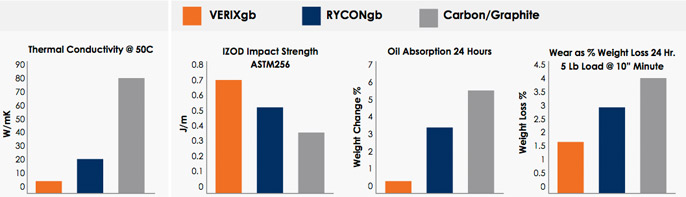

VERIXgb offers the following advantages over previously used carbon- graphite materials:

- High impact resistance and fracture toughness for improved component reliability.

- Easier to fabricate when compared to Carbon Graphite and ceramics, lower component cost to the consumer.

- Low thermal conductivity with no thermal shock avoiding checks and cracks in the hot glass.

- Low oil absorption improves component reliability, lowering incidents of cracks and checks. Improved plant output.

- Increased wear resistance for extended component life and lower manufacturing cost.